1 – INTRODUÇÃO

Durante o nosso dia-a-dia estamos expostos a vibrações, de uma forma ou de outra, em carros, autocarros, comboios, etc. Muitas pessoas estão também expostas a outras vibrações, durante o seu trabalho, por exemplo as produzidas por ferramentas manuais, máquinas ou veículos pesados.

Aqui vão ser apenas referidas as vibrações indesejáveis: o efeito da sobreexposição às vibrações; os diversos fatores que devem ser levados em conta quando é medida, como é medida e avaliada, e que acções podem ser desenvolvidas para reduzir fontes de vibrações prejudiciais e/ou perigosas.

2 – REFERÊNCIAS NORMATIVAS

As referências legais e normativas (em Portugal) são as seguintes:

- Decreto – Lei n.º 46/2006, de 24 de fevereiro

- NP EN ISO 5349-1:2009 – Vibrações Mecânicas – Medição e avaliação da exposição dos indivíduos às vibrações transmitidas pelo sistema mão – braço; Parte 1: Requisitos gerais;

- EN ISO 5349-2:2001 – Mechanical Vibration – Measurement and evalution of human exposure to hand-transmitted vibration – Part 2: Pratical guidance for measurement at workplace;

- Guia Relacre 21, Edição Setembro de 2008 – Exposição dos Trabalhadores às Vibrações – Apontamentos sobre Estimativa das Incertezas de Medição;

- Guia Relacre 23, Edição junho de 2014 – Guia de boas práticas de medição de Vibrações – Exposição dos Trabalhadores às Vibrações.

3 – EFEITOS DAS VIBRAÇÕES

Existem dois tipos principais de vibrações no corpo humano: vibrações no corpo inteiro e vibrações no conjunto mão-braço.

A vibração no Corpo Inteiro é transmitida ao corpo na sua globalidade, geralmente através da superfície de suporte (isto é, os pés, costas, nádegas, etc.). Uma pessoa a conduzir um veículo, por exemplo, está sujeita a vibrações no Corpo Inteiro através das nádegas, e se existir estiver recostada, também através das costas.

As vibrações na mão-braço são transmitidas às mãos e braços. É sobretudo suportada pelos operadores que utilizam ferramentas manuais.

O sistema do Corpo Inteiro e o sistema mão-braço são “mecanicamente diferentes” e são, portanto, estudados em separado.

A exposição diária a vibrações na mão-braço, ao longo de um período de anos, pode causar danos físicos permanentes normalmente resultando no designado “síndroma do dedo branco”, ou pode danificar as juntas e músculos do punho ou cotovelo.

O síndroma do dedo branco, nas suas fases avançadas, é caracterizado por um embranquecimento das extremidades dos dedos, o que é causado por danos nas artérias e nervos nos tecidos macios da mão. O síndroma normalmente afecta, em primeiro lugar um dedo, mas também vai afectar também os outros, se a exposição às vibrações mão-braço continuar. Nas fases inicias do “síndroma do dedo branco” os sintomas são, entre outros, perda de controlo e sensibilidade dos dedos afectados. Estes sintomas são sérios porque afectam não só as atividades profissionais, mas também as atividades de lazer, e são em grande medida irreversíveis.

As perdas de sensibilidade e controlo dos dedos, mesmo por curtos períodos de tempo, podem representar um perigo directo e imediato. Por exemplo quando períodos de exposição (utilização de ferramentas portáteis vibratórias) são alternados com trabalho manual de precisão. Esta situação é frequentemente encontrada, por exemplo em matadouros, onde os talhantes utilizam serras circulares e facas afiadas.

Os danos às juntas do punho e cotovelo são frequentemente causados pela exposição prolongada a vibrações produzidas por ferramentas de percussão (martelos pneumáticos e perfuradoras de rocha). Este dano causa dor nas juntas e nos músculos do antebraço e é acompanhada por redução de controlo e força muscular do mesmo.

4 PRINCÍPIOS DA AVALIAÇÃO DE RISCO

A avaliação dos riscos deve:

• identificar onde pode haver um risco derivado de vibrações transmitidas ao sistema mão-braço;

• medir as exposições dos trabalhadores e compará-las com o valor de acção da exposição e o valor-limite de exposição;

• identificar os controlos de risco disponíveis;

• identificar os passos que pretende dar para controlar e monitorizar os riscos de transmissão de vibrações ao sistema mão-braço;

• registar a avaliação, os passos que foram dados e a respectiva eficácia.

Um ponto de partida é considerar o trabalho que está a ser executado, os processos envolvidos e as ferramentas e equipamentos utilizados, e perguntar: «A empresa utiliza equipamento manual, guiado à mão ou alimentado manualmente?» Se for o caso, pode precisar de gerir as exposições a vibrações.

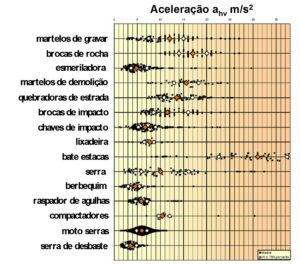

A figura apresenta exemplos de amplitudes das vibrações de algumas ferramentas e máquinas que criam os riscos.

É importante manter os trabalhadores e os seus representantes envolvidos e informados no processo de avaliação do risco de vibrações. Uma parceria eficiente com os trabalhadores ajudará a garantir que a informação usada para a avaliação do risco se baseia em avaliações realistas do trabalho que está a ser executado e do tempo gasto para fazer esse trabalho.

Os fatores que governam a exposição diária de uma pessoa às vibrações são a amplitude (nível) ponderada em frequência da vibração e o período de tempo durante o qual a pessoa lhe está exposta. Quanto maior a amplitude ou quanto mais longa a exposição, tanto maior será a exposição dessa pessoa às vibrações.

Os valores RMS de aceleração ponderados em frequência (aeq) associados à exposição ocupacional a vibrações na mão-braço encontram-se normalmente entre 2-50 m/s2 , enquanto os que se encontram na gama do corpo inteiro estão na gama de 0,1- 40 m/s2 .

5 DURAÇÃO DA EXPOSIÇÃO

Para avaliar a exposição diária a vibrações, é necessária uma estimação do tempo em que os operadores das ferramentas estão expostos à vibração. A experiência tem mostrado que isto é frequentemente sobrestimado durante a avaliação do risco. Seguidamente analisamos qual a informação sobre o tempo de exposição que é necessária e o modo de determiná-la.

Antes de poder estimar a exposição diária a vibrações, A(8), é preciso conhecer a duração diária total da exposição à vibração de cada ferramenta ou o processo utilizado. Só se deve contar o tempo em que o trabalhador está exposto à vibração; não se deve contar um período em que um trabalhador tenha pousado o equipamento ou em que esteja a segurá-lo sem estar em funcionamento.

O tempo de contacto é o tempo durante o qual as mãos estão efetivamente expostas à vibração proveniente da ferramenta ou da peça. Frequentemente, este período é muito inferior ao «tempo de trabalho» e é habitualmente sobrestimado pelos operadores. O método utilizado para estimar os tempos de funcionamento, depende frequentemente de a utilização da ferramenta ser contínua ou intermitente:

Operação contínua da ferramenta:

Exemplo: utilização de um triturador para eliminar grandes quantidades de um material durante várias horas.

Observar o trabalho durante uma parte representativa do dia de trabalho e registar durante quanto desse tempo a ferramenta está em funcionamento. Para tal, pode ser útil um cronómetro ou um registo em vídeo.

Operação intermitente das ferramentas:

Exemplo: Utilização de chave de aperto por percussão para apertar porcas das rodas de veículos.

Talvez se tenha acesso a informação sobre o número de operações realizadas durante o dia de trabalho (por exemplo, o número de componentes acabados por dia). Se se estimar a duração média de uma operação, observando o ritmo de trabalho durante um período escolhido como amostra, pode-se então calcular a duração diária total.

No exemplo da chave de aperto por percussão, talvez seja conhecido o número de rodas desmontadas e substituídas por dia e o número de porcas por roda, e também é necessário saber quanto tempo leva habitualmente a tirar ou substituir uma porca.

Os padrões de trabalho têm também de ser cuidadosamente levados em conta. É possível, por exemplo, que alguns trabalhadores só usem ferramentas vibratórias durante certos períodos de um dia ou de uma semana. Devem ser estabelecidos padrões de utilização habitual, pois serão um importante fator no cálculo da exposição provável do trabalhador às vibrações.

6 – CONCEITOS BÁSICOS DE MEDIÇÃO DE VIBRAÇÕES

A seguir pode ver uma apresentação sobre este tema.

https://pt.slideshare.net/CarlosAroeira/medio-de-vibraes

Se pretender ver informação mais detalhada clique aqui.

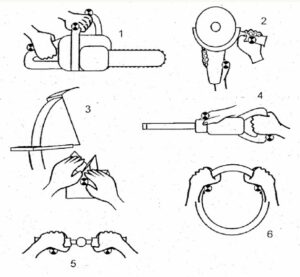

7 OS PONTOS DE MEDIDA MÃO-BRAÇO

Quando um objeto vibratório é seguro na mão, transmite as suas vibrações à mão e braço através da palma. O transdutor pode, portanto, ser montado entre a superfície de contacto entre a palma da mão e o objeto vibratório ou fixo na ferramenta.

Mesmo um acelerómetro pequeno colocado na palma da mão tende a perturbar a forma de o operador agarrar a ferramenta e leva, portanto, a medições incorretas. Uma solução prática consiste em montar o acelerómetro num adaptador que é então seguro na interface mão-ferramenta. Tanto o acelerómetro como o adaptador devem ser leves para não introduzirem o risco de ressonâncias.

8 – RESPOSTA EM FREQUÊNCIA DO CORPO HUMANO E PONDERAÇÃO

Para perceber a razão pela qual os seres humanos são mais sensíveis a algumas frequências que a outras é útil levar em consideração o corpo humano como um sistema mecânico. O sistema é complicado pelo facto de: (a) cada parte do corpo tem a sua maior sensibilidade em diferentes gamas de frequência; (b) o corpo humano não é simétrico, e (c) não existem duas pessoas a responder às vibrações exatamente da mesma forma. De qualquer modo, foram desenvolvidos modelos biomecânicos adequados para simular a resposta humana à vibração.

Se pretender ler mais informação sobre este tema clique aqui.

A seguir pode ver uma apresentação sobre este tema.

https://pt.slideshare.net/CarlosAroeira/avaliao-da-exposio-dos-trabalhadores-as-vibraes-ponderaes-em-frequencias

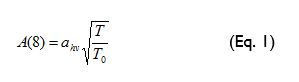

9 – O CÁLCULO DO A(8) – Exposição diária às vibrações

De acordo com a metodologia definida para o ensaio, são quantificadas as vibrações associadas a cada operação, por medição no equipamento, máquina ou posto de trabalho, sendo o valor de vibração final diária por trabalhador calculado em função do tempo de exposição a cada operação, a partir da fórmula da Eq. 1:

Onde,

T – Duração diária total da exposição às vibrações;

T0 – Duração de referência de 8 horas (28800s).

Sendo akwx, akwy e akwz os valores eficazes das acelerações ponderadas para os eixos x, y e z, respetivamente.

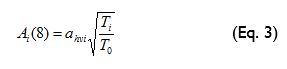

Quando o trabalhador desempenha mais do que uma operação, expondo-se às vibrações resultantes das mesmas, o formulário a usar é o seguinte: Eq.3 e Eq.4;

Assim, o valor de exposição diária é dado pela equação seguinte:

Onde i representa uma operação do conjunto total das operações executadas pelo trabalhador.

10 – VALORES LIMITE – DECRETO-LEI 46/2006

Valores limite de exposição e valores de exposição que desencadeiam a ação:

Para as vibrações transmitidas ao sistema mão-braço:

a) O valor limite de exposição diária normalizada, correspondente a um período de referência de 8 horas, é fixado em 5 m/s2;

b) O valor de exposição diária normalizada, correspondente a um período de referência de 8 horas, que desencadeia a ação é fixado em 2,5 m/s2.

A seguir pode ver uma apresentação sobre este tema.

https://pt.slideshare.net/CarlosAroeira/avaliao-da-exposio-dos-trabalhadores-s-vibraes-mao-braco